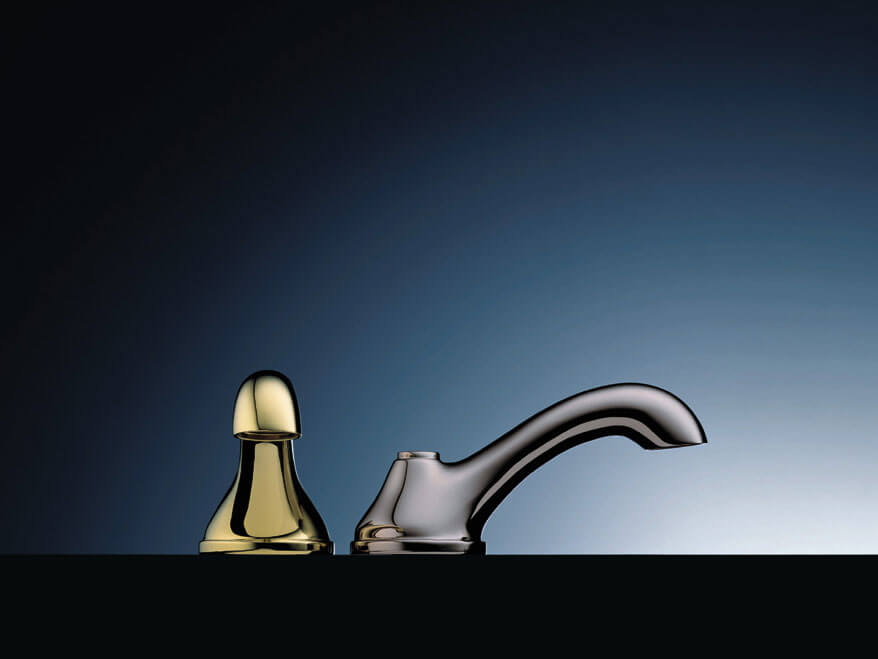

Timeless beauty and flawless function protected by our advanced coating processes

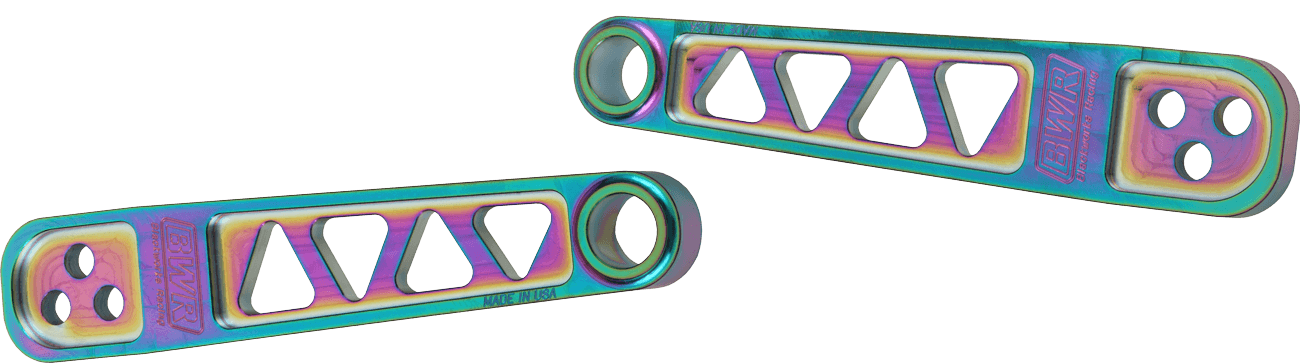

Richkote™ incorporates the latest decorative PVD coating technology to produce standard BHMA finishes, as well as non-traditional and custom colors. Richkote™ uses both “in line” and batch style systems to deliver finishes that are smoother, brighter, and harder than what can be achieved through typical plating methods. The color uniformity of our coatings from cycle-to-cycle and year-to-year is tightly controlled in order to ensure customer satisfaction. Our Richkote™ PVD coatings’ durability, varied color options, and unmatched finish make it the premier surface treatment choice.

Benefits of Richkote™ PVD Coating

- Superior Wear Resistance – Richkote™ PVD coatings are very hard (Micro-Hardness > 80 Rc). This high hardness provides excellent scratch and scuff resistance in a thin-film layer (0.2-0.5 µm).

- Excellent Adhesion – the coatings exhibit a strong physical bond to the substrate (>25N), and is not prone to the micro-fracturing seen in electrolytic plating processes.

- Conformal Coating – the coating will take on the existing surface finish: pre-existing matte, brushed & polished finishes will be replicated.

- Substrate Flexibility – Richkote™ PVD is suitable for a wide range of base materials: stainless steels, tool steels, titanium, aluminum, brass, zinc die-castings, ABS plastics, and more. (Note: some materials may require pre-coating plating with Ni & Cr in order to be suitable for this coating process)

- Color Replication – Between frozen process controls and quality assurance, the Richkote™ process will consistently produce colors from order to order.

- UV Protection – PVD films are inorganic and, thus, impervious to ultraviolet degradation. No organic clear topcoats are required.

- Color Fastness – PVD films are colorfast over time.

- Biocompatible – Richkote™ PVD coatings are chemically inert and hypoallergenic.

- Versatility – Using our Richkote™ PVD coatings can allow a customer to transform a single un-coated substrate into a virtually limitless product line, simply by changing the appearance with our coatings.

- Environmentally Friendly – Richkote™ PVD is a 100% environmentally friendly manufacturing process, with no harmful waste products. Additionally, these coatings are all RoHS compliant.

Typical applications for the Richkote™ Process

- Kitchen & Bathroom (Plumbing Fixtures)

- Door & Window Hardware

- Automotive (Interior & Exterior)

- Marine Hardware & Trim

- Watches

- Jewelry

- Aircraft Interiors

- Appliances

- Architectural

- Firearms

- Cutlery

- Musical Instruments

- Fashion Accessories

- Signs & Displays

- Consumer Products

- …the only limit is your imagination!

Suitable materials for the Richkote™ Process

- Stainless Steel

- Tool Steel

- Carbon Steel

- Alloy Steel

- Titanium

- Tungsten

- Cobalt

- Aluminum*

- Brass*

- ABS Plastic*

- Zinc Die-Castings*

- Bronze*

Richkote™ PVD Coatings

- Anthracite

- Black

- Brass

- Bronze

- Champagne

- Copper

- Coyote

- Flat Dark Earth

- Gold

- Graphite

- Nickel

- Oil-Rubbed Bronze

- Rainbow

- Rose Gold

- Stainless Steel

- Custom Colors, upon request