Richter Precision Inc. possesses a modern thin films and metallurgical laboratory to allow characterization of the mechanical, physical and elemental properties of thin films and materials. While the primary function of this laboratory is to support our on-going Research & Development and Quality Control efforts, this facility is also available for commercial projects.

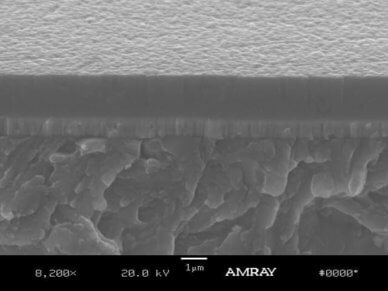

High resolution scanning electron microscopy (SEM) may be undertaken using our AMRAY 1850 microscope equipped with a field emission source, secondary electron and back scatter detectors and a qualitative/quantitative energy dispersive X-ray detector system. The scanning electron microscope (SEM) is an instrument that creates images at magnifications ranging from 20 -100,000 times by focusing and rastering a high energy beam of electrons onto the surface of a sample and detecting signals from the interaction of the incident electrons with the sample’s surface.

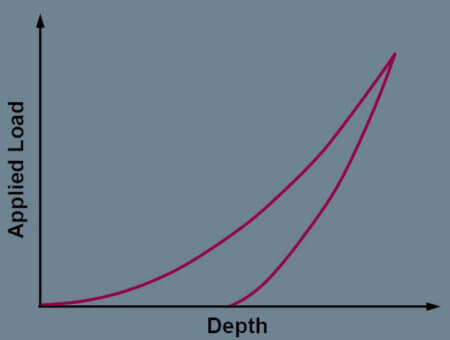

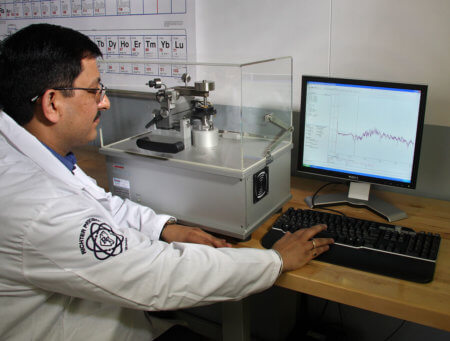

Nano-Indention Tester

Film hardness and elastic properties can be derived using a CSM nano-indentation tester. Indentation testers are high precision instruments used for the characterization of mechanical properties of thin films, coatings and substrates. Properties such as hardness and elastic modulus can be determined on almost any type of material: soft, hard, brittle or ductile. A Berkovich diamond indenter tip is driven into the sample by applying an increasing load up to a predefined value. The load is then decreased until partial or complete relaxation of the material. The resultant load-depth curve is then used to calculate mechanical properties such as hardness and elastic modulus.

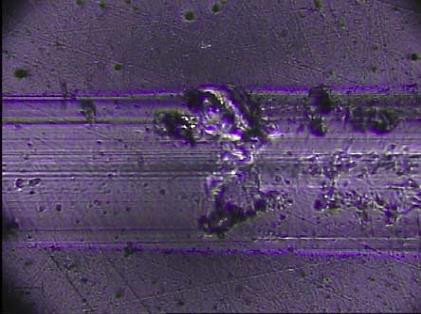

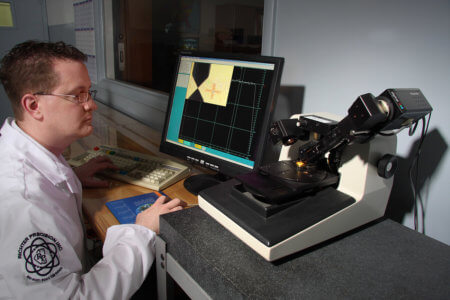

Coating adhesion can be tested using our CSM Revetest dynamic scratch adhesion tester. This unit is equipped with an acoustic emission detector and image capture & measurement system. This technique involves generating a controlled scratch on a selected area. The tip material (normally diamond) is drawn across the coated surface under constant, incremental or progressive load. At a certain critical load the coating will start to fail. The critical load data is used to quantify the adhesive properties of different film – substrate combinations.

Tribological performance of thin films may be assessed using a CSM pin-on-disc sliding wear tribometer. A flat or a sphere shaped indenter is loaded on to the test sample with a precisely known weight. A pin is mounted on a stiff lever, designed as a friction less force transducer. As the sample is either rotating or sliding, resulting frictional forces acting between the pin and the sample are measured by very small deflections of the lever. Wear coefficients for both the sample and material are calculated from the volume of the material lost during a specific friction run.

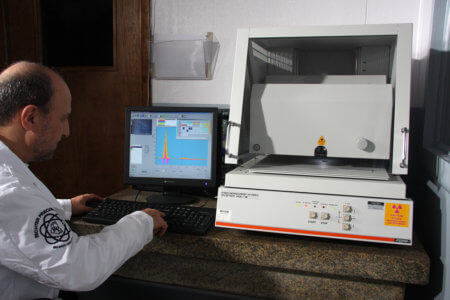

Thin film thickness may be derived using our CSEM Calotest® or FischerScope XDL-B X-ray fluorescence equipment.

Richter Precision Inc. collaborates and has commercial agreements in place with a number of highly respected universities and organizations around the globe. Such contact allows for more specialized or non-routine characterization efforts to take place.