Boronizing (also known as boriding) is a high temperature thermo-chemical surface hardening process in which boron atoms are diffused into the surface of a work piece to form complex borides (i.e. – FeB/FeB2) with the base metal. There is no mechanical interface between the complex borides and the substrate as this is a true diffusion process. The resulting case layer has a hard, lubricious surface capable of performing at higher temperatures than most surface treatments. Practically any ferrous material can be boronized, as well as many Ni, Ti & Co alloys. However, it is important to note that the higher the content of alloy elements, the slower the diffusion rate.

Boronizing (also known as boriding) is a high temperature thermo-chemical surface hardening process in which boron atoms are diffused into the surface of a work piece to form complex borides (i.e. – FeB/FeB2) with the base metal. There is no mechanical interface between the complex borides and the substrate as this is a true diffusion process. The resulting case layer has a hard, lubricious surface capable of performing at higher temperatures than most surface treatments. Practically any ferrous material can be boronized, as well as many Ni, Ti & Co alloys. However, it is important to note that the higher the content of alloy elements, the slower the diffusion rate.

General Characteristics of Boronizing

- High temperature process (850˚ C/1562˚ F typical for ferrous materials)

- High hardness (1600-1900 HV in ferrous materials) of case layer

- Reduced coefficient of friction (0.4)

- High resistance to temperature (approx. 1200° F)

- Increases resistance to acids (especially Hydrochloric acid)

- Boronized layer can be polished after processing

- Reduced tendency to cold weld

- Suitable for a broad range of materials

- Boronized layer can be selectively applied

- Surface treatment can be uniformly applied to irregular shapes

- Heat treatable materials can be fully hardened after boronizing

- Uniform case depths of diffusion layers are controllable

Titankote™ B – Boronizing Technical Data

| Proprietary Name | Type | Composition | Color | Case Depth (microns) | Micro-Hardness (HV) | Coefficient of Friction | Maximum Working Temperature | Coating Process Temperature |

|---|---|---|---|---|---|---|---|---|

| Titankote™ B | Diffusion | Complex Borides* | Gray | 10-200** | 1600-1900*** | 0.4 | 650˚C/1202F˚ | 850˚C/1562F˚ **** |

* – The composition of the diffused layer will vary depending on the base material. For example, ferrous materials will form FeB/FeB2; nickel-based alloys will form Ni4B3/Ni2B/Ni3B; cobalt-based alloys form CoB/Co2B/Co3B; titanium-based alloys form TiB/TiB2.

** – The thickness/depth of the borided layer will vary depending on the base material. Ferrous materials will develop thicker layers; materials with a higher content of alloy elements tend to produce thinner layers.

*** – The micro-hardness of the diffused layer will vary depending on the base material. For example, FeB/FeB2 layers will have a micro-hardness in the range of 1600-1900 HV. Other elements, such as Ni, Ti and Co, will produce a different hardness range, some even higher than FeB/FeB2.

**** – The processing temperature will vary depending upon the base material. The temperature shown in the table is a common processing temperature for ferrous materials.

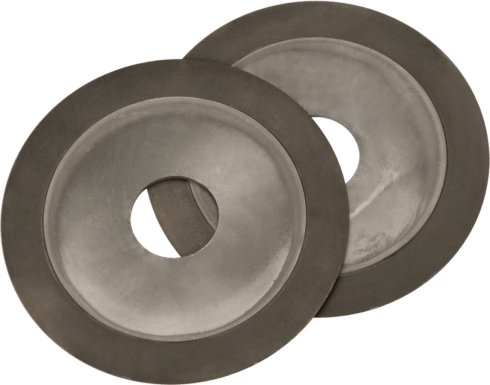

Typical Applications for Boronizing

Tooling

- Hot forging dies

- Wire drawing dies

- Extrusion dies

- Straightening Rolls

- Ingot molds

Oil & Gas Components

- Production tubing

- Valve components

- Valve fittings

- Metal seals

- Coal/Oil burner nozzles

General Components

- Nozzles

- Plungers

- Gears

- Shafts

- Rollers

Miscellaneous

- Turbine components

- Pump impellers

- Ball valves & seats

- Shaft protection sleeve

- Guide bars

Suitable Materials for the Boronizing Process

This list is representational, but not all-inclusive: please contact us with questions regarding your specific application substrate.

Ferrous Metals

- Carbon steels

- Low alloy steels

- Tool steels (H13, D2, etc.)

- Stainless steels

- Gray & ductile cast iron

Non-Ferrous Metals*

- Tantalum

- Titanium

- Tungsten

- Niobium

- Molybdenum

Ti & Ni Based Alloys*

- Ti-6Al-4V

- Inconel 718

- Inconel 625

- Hastelloy

- Nimonic 80A

*- these materials typically require special processing, and are not available as a standard process.